The Most Used Pocket Knife Lock Types

Think of the lock on your pocket knife like the one on your front door. You want a dependable lock that will keep the danger at bay, yet also be easy to open and close. A knife lock should ensure great lockup and provide maximum confidence in the blade staying right where you want it. The lock in a pocket knife is likely the most integral part of a knife design because nothing will ruin your day faster than a sharp blade closing on those freshly manicured digits you just had done at the spa. Ain't nobody want stitches, amigos.

LINER LOCK

Michael Walker perfected the idea of a liner of the knife that is tensioned inward. This tension on the lock keeps the blade closed with a detent ball and secures it open on the lock face. Fun fact (heard through the grapevine, likely true): Michael Walker never defended his patent on the liner lock, so it entered the public domain, and he never received royalties for its use. It's an interesting twist on the most prolific modern locking mechanism. The Banter Series, Civivi Cedar, and the Knafs Lander utilize the liner lock.

How to Close a Liner Lock Pocket Knife

Push the lock outward, allowing the blade to fold. Fold the blade until you feel the detent contention. This can be done with just one hand.

FRAME LOCK

The Integral Lock or “frame lock” is a Chris Reeve invention that works like a liner lock, but is cut from the frame of the handle. This creates an integrated lock and handle in a single piece. Frame locks are made from Titanium or stainless steel. When made well, frame locks are extremely strong and dependable. If you're new to the knife game, you may find that frame locks are hard to open (guilty as charged over here!). You likely have your finger on the frame lock, thus pushing the detent ball into the blade. Move your index finger to the pocket clip, and it will likely open like a dream.

How to Close a Frame Lock Pocket Knife

Push the frame outwards, giving the blade the necessary room for it to close. Then, simple push the blade close, until you feel the detent make the connection so it remains closed.

BUTTON LOCK

Also called a “plunge lock,” the button lock is common on automatic knives. How does this knife lock work? A cutout in the blade tang engages with a spring-loaded button to hold the knife open. To release, push the button down and swing the blade closed. Within the last year, companies like WE Knife have made this knife lock type popular on regular flippers, and Brian Tighe also seems to have a penchant for that particular configuration. One of the main benefits of this locking mechanism, is that your finger is never in the path of the blade when closing the knife. This makes it a very safe tool to manipulate.

How to Close a Button Lock Pocket Knife

Simply depress the button and fold the blade shut while maintaining pressure on the button. In an automatic configuration, this should always be done with both hands. In a regular flipper, this is very easy to do with just one hand.

BACK LOCK

Popularized by the iconic Buck 110 folding hunter, the back lock has a rocker arm that pivots on a center pin. When open, the lug connects with a notch in the blade tang and a tension bar keeps the lug in place. While many of the newer locking mechanisms enable us to open and close pocket knives with one hand, the back lock doesn't hold the same benefit. However, it is known and respected as a very strong lock type in the knife world. It is also an ambidextrous lock, which means the knife will be equally comfortable to open and close for both right handed and left handed people.

How to Close a Pocket Knife with a Back Lock

To close, push the rocker arm in to release the lug and fold blade.

SLIP JOINT

A simple design with a tensioned backspring that presses against the blade to keep it closed. To open, a nail nick is used to overcome the spring tension. The backspring sits against the backstop to hold the blade open as a “non-locking folder.” Tension keeps the blade open, but care is needed to avoid putting pressure in the wrong direction and closing the blade unexpectedly. This is why nowadays many of these pocket knives have a half stop mechanism, to help prevent accidents and stitches. Traditional knives like the well-used one grandpa used to carry are often slip joint designs.

How to Close a Slip Joint Pocket Knife

Carefully fold the blade. Be careful with those fingers.

CROSSBAR LOCK (AXIS LOCK)

McHenry and Williams invented. Benchmade launched this mechanism under the name of the Axis Lock. Now public domain. It has a sliding lock that connects to an omega spring attached to the liner. The sliding lock presses into a backstop in the blade to secure the knife open and it functions as a detent when it’s closed. You haven't felt joy until you get your hands on a buttery smooth crossbar lock. Sometimes it's all about the small things in life. Side note: In 2018, the utility patent expired on the Axis lock, and the mechanism entered the public domain. Every company that uses it calls it a different name, but everybody knows they owe a little nod to Benchmade for the technology. We have the Knafs Lander 2 in a crossbar configuration.

How to Close a Pocket Knife with a Crossbar Lock

Simple pinch the crossbar from both sides, and fold the blade shut as you do so. This can be done with one or 2 hands.

COMPRESSION LOCK

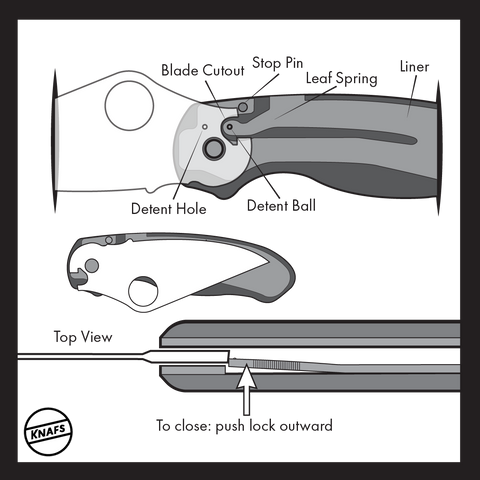

This Spyderco invention works like a liner lock on the back of the handle: a leaf spring is cut from the liner and engages in a blade tang cutout. A detent ball on the liner connects with a detent hole to keep the blade closed. Think of the compression lock like a reverse liner lock, but easier to fidget with and stronger overall. Is that the definition of "the best of both worlds?" You be the judge! Because the lock in this mechanism is placed on the back of the knife, your fingers won't be on the path of the blade as you close it. Another great benefit to this knife lock type!

How to Close a Pocket Knife with a Compression Lock

To close, simply push the liner in the back side of the handle outwards, and close the blade as you do so. This can be done very easily with just one hand.

CLASP LOCK

The clasp lock is a light-duty mechanism that works via a pin on the blade tang. The pin slides into a lock hole in the rocker arm or “clasp” to hold the blade open. Clasp locks date back centuries to Spain, the land of flamenco and running bulls. The mechanism it self works similar to a back lock, but the lock is external to the handle instead of being recessed into it.

How to Close a Clasp Lock Pocket Knife

Simply pull the ring and fold the blade shut.

FRICTION FOLDER

The earliest Roman folding knives were friction folders. The user grips the handle, plus the extended tang, creating friction on the stop pin. This is a “non-locking folder,” bypassing bad knife laws that restrict carry of certain knife types. The most popular modern friction folder is the Svord brand from New Zealand.

How to Close a Friction Folder Knife

Simply fold the knife.

BOLSTER LOCK

Found on Italian stilettos, this lock is a rocker arm against a backstop. To close: a pivoting bolster releases the rocker arm. A firing button with a lug inserts into a detent hole to keep it closed. Press the button to release the lug and fire the torsion spring.